The Story Behind Our Lancashire-Made Cloud Cotton Blankets – The British Blanket Firm

Our new Cloud Cotton blanket designs started life in Bristol and have been woven for us in Lancashire, at a weaving mill with greater than 150 years of historical past. The truth is, Burnley as soon as had extra looms than there have been folks! It’s a place the place textile abilities have been handed down by way of generations, and the place conventional looms nonetheless clatter away alongside a contemporary method to design and sustainability.

In right now’s weblog, we’ll head behind the scenes within the mill the place our Cloud Cotton blankets are made, be taught extra about recycled cotton blankets, and achieve an perception into the craft of cotton jacquard weaving.

The British Blanket Firm proudly makes all its blankets within the UK and Eire, supporting native jobs and preserving conventional crafts. The Cloud Cotton blanket vary is woven in Lancashire

Lancashire’s textile heritage

Lancashire was as soon as often known as the textile capital of the world. Many mills have since fallen silent, however a small quantity stay, protecting this essential craft alive. Our mill is one in every of them. It has tailored with the occasions however by no means overpassed the values of high quality and care which have at all times outlined British weaving.

From design to loom

Working with recycled cotton is not any simple job. The fibres are shorter than virgin cotton, which makes them more difficult to weave. That’s the place the talent of the Lancashire weavers is available in.

For Cloud Cotton, the designs are delivered to life on jacquard looms, which make it doable to create complicated reversible patterns and curved strains. This technical capacity permits our designs to circulation throughout the material in a means that feels natural and balanced.

Not like dobby looms that may solely weave straight strains, jacquard looms can create woven patterns with curves, permitting us to design blankets with sweeping shapes and a totally reversible construction

Not like dobby looms that may solely weave straight strains, jacquard looms can create woven patterns with curves, permitting us to design blankets with sweeping shapes and a totally reversible construction

How a Cloud Cotton blanket is made

-

Accumulating cloth waste

Our journey begins by gathering post-production cotton offcuts, the excess cloth left behind from garment manufacturing and pattern-cutting. -

Sorting and preparation

The material is rigorously sorted by recycling consultants. Any non-cotton components, reminiscent of zips or buttons, are eliminated, and the items are organised by color, prepared for transformation. -

Breaking down the fibres

Utilizing specialist tools, the cotton is damaged again down into uncooked fibres. This step is essential to make sure a high-quality base for spinning. -

Spinning new yarn

As soon as reworked, the fibres are spun into recent yarns, every carrying the character of the recycled textiles it got here from. No extra dye is required as the colors are retained from the unique materials. -

Weaving on jacquard looms

The brand new yarns are woven into fabric on jacquard looms, which permit us to create reversible patterns and mushy, flowing strains. That is the second our designs come to life. -

Ending by hand

Every blanket is raised, brushed and inspected earlier than being completed with a neat blanket-stitch border. This sewn edge strengthens the material and provides a conventional contact.

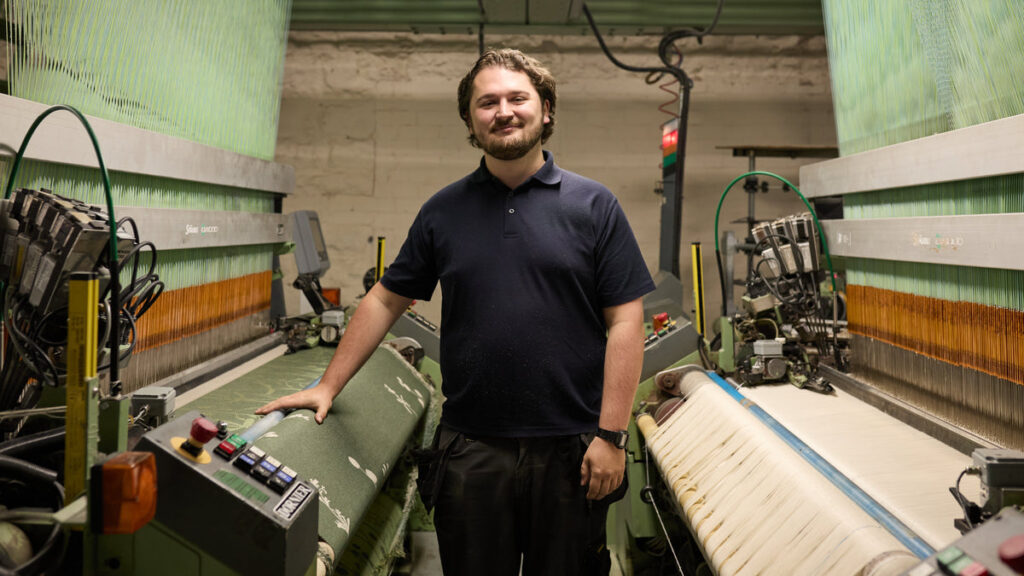

Every stage of the weaving and ending course of is overseen by expert artisans, who’re consultants of their craft. Combining a recent design aesthetic with conventional craftsmanship is central to The British Blanket Firm’s mission

Sustainability on the coronary heart

The Cloud Cotton assortment offers new life to materials that may in any other case have been wasted. With no further dyes required and each fibre put to make use of, the method helps scale back textile waste and restrict the demand for virgin sources. It’s a means of weaving that takes fashionable environmental tasks significantly, whereas additionally celebrating the centuries-old talent of British makers.

Recycled cotton makes use of as much as 80% water than virgin cotton as a result of it would not require cultivation and dying. Virgin cotton manufacturing could be very water-intensive, with one kilogram of material requiring as much as 10,000 litres of water, whereas recycling cotton repurposes present supplies, decreasing the necessity for brand new crops, land, and pesticides.

The British Blanket Firm makes mushy and exquisite blankets from recycled wool and recycled cotton.

Recycled cotton is a sustainable different to virgin cotton blankets because the re-use present supplies and use much less water and vitality to fabricate. Our Cloud Cotton blankets are brushed for a particularly mushy and lofty end, that feels as fluffy and thick as fleece, however is pure

The folks behind the method

Behind each blanket are the craftspeople whose information makes all of the distinction. From organising the looms to checking every bit because it comes off the road and stitching the blanket-stitch border, their consideration to element is what turns recycled yarn into one thing mushy, balanced and enduring. Their delight within the work is obvious in each sew thread.

While you deliver a Cloud Cotton blanket into your property, you might be welcoming a chunk that has been made with take care of the heritage of weaving and the atmosphere. These blankets replicate the whole lot we stand for at The British Blanket Firm: considerate design, genuine craftsmanship and pure supplies, made to be a part of your life for years to return.