Expertise and Manufacturing » BedTimes Journal

Tools producers are innovating methods to automate bedding manufacturing, highlighting the significance of automation in bedding manufacturing.

I really feel the necessity, the necessity for velocity.” That iconic line from the film “High Gun” summarizes the state of bedding equipment. And whereas creating sooner equipment is crucial in a aggressive market, suppliers are additionally innovating methods to scale back labor and be extra correct and sustainable.

Innovating for Much less Packaging

Decreasing packaging quantity has been a key focus for equipment suppliers in recent times. Much less packaging permits extra models per delivery container, resulting in decrease emissions and decreased delivery prices.

“Let’s say — within the final 10 years — we all know methods to smash the product and get it to be as small as attainable,” says Mark DeCoteau, director of U.S. operations for Verona, Italy-based Dolphinpack. “So, I don’t suppose that’s the place issues are going to go. It’s extra about how we service the purchasers. How will we scale back their waste or scale back their price within the quantity of plastic they use? And likewise the quantity of labor they use.”

Tackling Labor Challenges with Modern Equipment

One of many largest priorities in equipment as we speak is labor discount — significantly end-to-end automation that eliminates handbook labor in historically ignored areas.

Paul Block, president of gross sales at Gribetz, says this can be a focus for the Dawn, Florida-based firm (fashioned after the acquisition of International Programs Group by ABM Worldwide earlier this yr). “The mattress business has been dealing with many challenges since Covid,” Block says. “We consider the only largest problem our prospects face is centered on the supply of expert labor, and it’ll require a brand new age of manufacturing equipment that may enhance effectivity, scale back waste and simplify meeting.”

Mitch Nussbaum, advertising specialist at C3, a equipment provider in Appleton, Wisconsin, echoes Block’s sentiments. “Labor stays a key stress level for our prospects, and it’s not going away. Over the subsequent three to 5 years, we see equipment persevering with to evolve by means of focused automation — strategically positioned methods that scale back reliance on handbook labor with out overcomplicating operations. Good equipment will change into extra user-friendly, extra linked and extra scalable — supporting producers who want flexibility with out sacrificing efficiency.”

Finish-to-Finish Automation and Good Equipment

Labor discount goes hand in hand with automation. “With rising prices, tighter margins and fierce competitors, producers wish to decrease waste, enhance in-house capabilities and streamline operations,” says Dhruvin Patel, world gross sales supervisor at Bursa, Turkey-based Elektroteks.

C3’s Finish-of-Line Automation System, launched in January, handles every part from case erection by means of palletizing. It supplies producers with a totally built-in end-of-line workflow that improves throughput and reduces handbook dealing with. Its upcoming Excessive Scale Automation for Hybrid Mattress Building, launching in September, is designed to deal with complicated assemblies like hybrid mattresses.

camera-based system to align adhesive paths.

Atlanta Attachment Co.’s most up-to-date innovation isn’t a chunk of kit however controls. With its Gateway 2.0 launch, it built-in its proprietary serial bus management system with an industrial PC, permitting it to leverage the advantages of connectivity and peripherals of the PC ecosystem. Customers can remotely (by way of server or the cloud) add and obtain manufacturing schedules, distinctive recipes and parameters for beds, view manufacturing knowledge, obtain upkeep suggestions from knowledge and push settings out from a central location.

“Since you’re linked to an industrial PC, you allow fast integration of peripherals like barcode scanners, RFID scanners and printers,” says John Chamlee, vp of enterprise growth on the Lawrenceville, Georgia-based provider. “The ability of the PC connection permits straightforward future integration of AI. We’re permitting prospects to rapidly and cheaply replace their 20-year-old machines to leverage this sort of connectivity. Because the system makes use of our serial bus management system because the machine I/O (enter/output) spine, we will do that with out the necessity to throw out present controls and wiring.”

In accordance with Block, ABM’s core strengths are additionally in software program growth and servo controls. “Our mission is to design, construct and manufacture a full line of extremely automated, most price efficient mattress producing tools within the business,” Block says. “Many of those progressive machines have been recreation changers for the world of mattress manufacturing and turned staples of each mattress manufacturing facility. These included numerous fashions of quilting machines, flanging machines, binding machines, label and restore machines, conveyor and materials dealing with tools, and plenty of others.”

At Dolphinpack, the corporate has been upgrading its machines, together with having the ability to seal plastic at a thinner gauge, thus decreasing the plastic essential to compress, fold and roll a mattress as much as 65%, and automation instruments like high quality management, which makes use of cameras and synthetic intelligence. “It helps standardize the method and decrease timing. For those who’re operating a manufacturing facility 5 or 6 days every week, it turns into an enormous benefit,” says Matteo Tagliaferri, world gross sales supervisor for Dolphinpack.

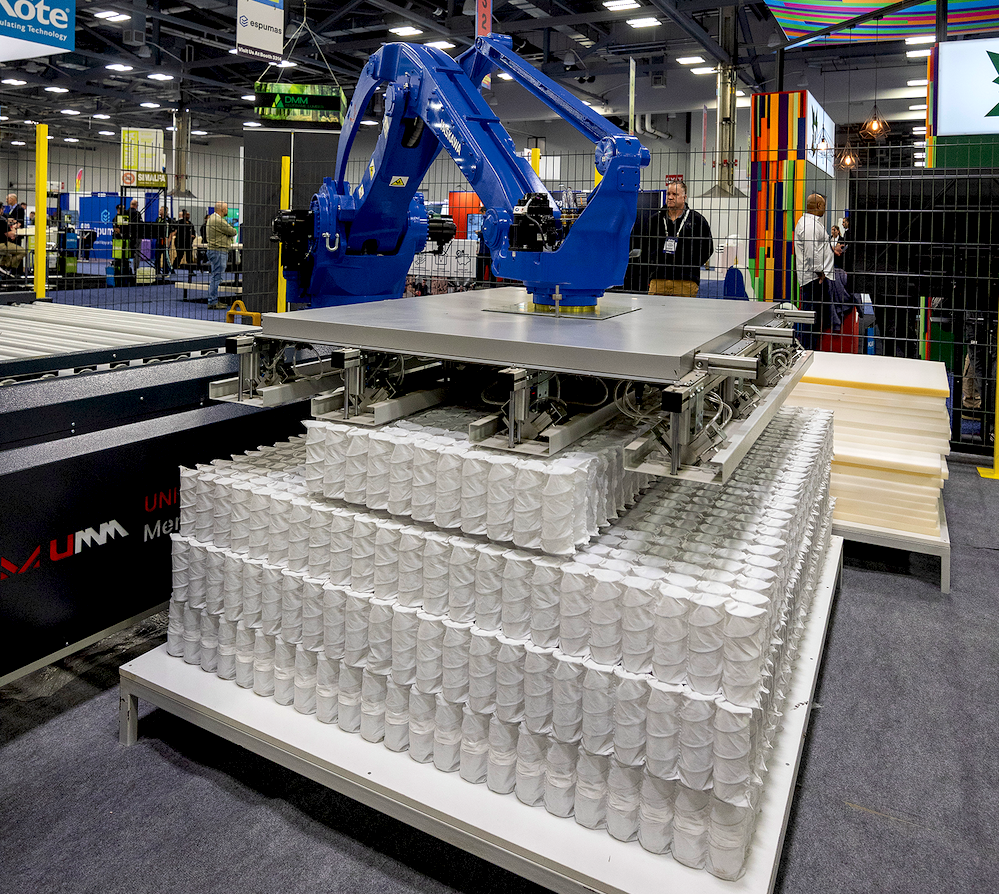

Michael Porter Jr., co-founder of United Mert Makina, headquartered in Delray Seaside, Florida, says whole automation isn’t life like. “Individuals have been making an attempt to completely automate and scale back all human participation in mattress manufacturing. Primarily based on the character of the product, that may by no means work, particularly for high-end mattresses,” he says. “UMM is working to develop equipment that includes automation to make mattress producers’ lives simpler, however with machines that work long-term within the discipline.”

The Rise of Imaginative and prescient-Primarily based Expertise in Equipment

Imaginative and prescient methods — automated instruments that mimic human sight — have gotten central to automation.

Earlier this yr at Interzum Cologne in Cologne, Germany, C3 debuted an up to date model of its Imaginative and prescient-Primarily based Sizzling Soften Utility, an clever gluing system that makes use of imaginative and prescient to detect every half and apply adhesive exactly, no recipes required. It adapts in real-time to half variation, enhancing velocity, accuracy and decreasing changeover time.

“This resolution eliminates the necessity for conventional gluing recipes, utilizing a camera-based system to find and align adhesive paths based mostly on real-time half geometry,” Nussbaum says. “It solves a typical bottleneck in manufacturing — slowing down for changeovers or minor half variations. With this know-how, producers can repeatedly run completely different elements at excessive velocity — as much as one half each six seconds — with out sacrificing precision or throughput.”

Elektroteks has additionally automated its manufacturing traces with RFID, imaginative and prescient methods and barcode integration. Now, with its FoamET and NEXUS methods, it has been in a position to apply the identical stage of automation to its foam dealing with enterprise, Patel says.

The Subsequent Frontier: AI-Powered Manufacturing

Past imaginative and prescient methods, AI is the subsequent step in good equipment.

“I believe that equipment normally will start to include AI into their DNA and change into increasingly more worthwhile to the consumer, particularly in its means to troubleshoot and provide options to the consumer,” AAC’s Chamlee says. “Actually, AI will proceed to push into areas of high quality management and secondary processes. Issues that are actually processed exterior of the manufacturing line and outdoors of the ‘equipment’ will change into integral with out the necessity of outdoor processes.”

That’s additionally true at Elektroteks. “Our purpose is steady innovation — enhancing velocity, flexibility and integration based mostly on buyer wants and market calls for,” Patel says. “With AI on the heart, future methods will likely be smarter, extra predictive and much more sustainable. We’re investing closely in AI. Our upcoming AI Agent will assist handle predictive upkeep, service schedules, batch manufacturing and extra — all aimed toward enhancing effectivity and decreasing downtime.”

In accordance with Patel, Elektroteks can also be working towards totally linked, AI-driven amenities known as “darkish factories,” requiring minimal human intervention.

Block is optimistic about AI, too. “Gribetz makes use of all accessible technical instruments with a purpose to discover methods to enhance machine effectivity,” he says. “Synthetic intelligence provides so many wonderful new methods to strategy machine design and help. We’re extraordinarily excited for the long run.”

The Give attention to Sustainable Equipment and Supplies

Alongside velocity and AI integration, sustainability is one other high precedence. For instance, Dolphinpack launched an improved model of Etesian machine named Good Hybrid, which permits for packaging gadgets in paper, somewhat than plastic. Such a shift reduces as a lot as 96% of the plastic used to compress, fold and roll mattresses, firm officers say. Beginning in 2022, they collaborated with main producers to assist them transition to paper packaging for mattresses and fabric gadgets. “In 2023, we ran six months’ price of testing in our manufacturing facility on our machines as a result of we have been the primary ones to have applied paper within the modeling,” Tagliaferri says.

In the meantime, at C3, the corporate is engaged on packaging options and methods longevity, “so prospects can scale back waste whereas extending machine life,” Nussbaum says. One instance is C3’s Topper Packaging System, up to date in late 2023, a versatile packaging resolution that permits prospects to make use of stretch movie or paper, relying on sustainability targets or price preferences.

To optimize useful resource utilization and lower waste, Elektroteks is leveraging AI by means of its Elek-AI platform. That, in response to Patel, paired with its next-gen, batch-mode will likely be a robust mixture.

Sustainability can also be a spotlight at Gribetz. “Gribetz machines are held to excessive requirements of vitality effectivity, waste discount and use of sturdy, recyclable supplies,” Block says. “Many present Gribetz machines use strategies for decreasing scrap and saving our prospects capital on this effectivity. We offer our prospects with scrap removing and baling methods that utterly automate the scrap removing course of and get rid of nonvalue-added labor from the method.”

Buyer-Centric Strategy to Equipment

Though machines are getting sooner and smarter, one facet of automated equipment is timeless, and that’s customer support.

Dolphinpack highlights its world response. “Our buyer help is implausible,” DeCoteau says. “You promote the tools, nevertheless it runs daily. We will reply globally. We’ve got 1,200 items of kit within the discipline on 5 continents.”

At Gribetz, the corporate is targeted on america. “The purpose of the brand new Gribetz firm is to change into the main provider of equipment to the mattress business by means of improvements in design and unmatched customer support,” Block says. “Our business wants a sturdy U.S.-based tools firm with manufacturing and repair proper right here within the U.S. Our prospects are giving us wonderful suggestions. We’re listening and listen to what they need from an tools firm.”

Subsequent-Technology Improvements and Business Predictions

As for what’s subsequent for UMM, the corporate is holding it beneath wraps for now, however teases a serious tools reveal at ISPA EXPO 2026, which is able to happen March 10-12 in Orlando, Florida. “It’s one thing no one else has proper now and can open up main doorways for mattress producers,” Porter says.

For Gribetz, Block says the brand new possession is taking a look at many challenges dealing with mattress manufacturing and its engineering crew is engaged on improvements that the corporate will introduce within the close to future.

“We’re working to enhance most of the earlier belongings of Gribetz,” Block says. “Via steady enchancment, high quality management and a powerful engineering crew, now we have the flexibility to react to developments and transfer rapidly. ABM Worldwide is a fourth-generation, family-owned and operated firm that has been constructing quilting machines and automatic stitching methods for almost 80 years. This brings a recent perspective and imaginative and prescient to how the present tools can perform with each minor updates and new designs. Neal Schwarzberger is an progressive proprietor who brings hands-on expertise to this group. He works tirelessly and his perspective is hyperfocused on the potential of machines and buyer help.”

Rising Developments in Mattress Manufacturing

Whereas priorities range by firm, a number of developments stand out. Nussbaum notes rising demand for foam encasement for coil models, prompting C3 to develop automation that applies foam tubs immediately in-line with coil manufacturing, eliminating steps. He additionally sees stronger demand for modular methods that help scalability and sooner changeovers.

Chamlee says border aesthetics stay a cheap means for producers to distinguish their merchandise, noting an elevated emphasis on new deal with designs and ornamental border schemes. In October 2024, Elektroteks acquired Cologne-based quilting machine producer Mammut to increase capabilities, with Patel observing sturdy curiosity in border quilting traces and in reducing foam in-house to scale back reliance on suppliers.

Block predicts main modifications in mattress manufacturing strategies. “I consider that our prospects are going to see modifications to the way in which they’re serviced by equipment corporations, or we’ll set the usual and pave the way in which for others to both comply with or be left behind,” he says. “Our prospects will at all times be searching for new developments in equipment and searching for pathways to scale back labor and enhance effectivity. We count on to be main these developments and serving to our prospects discover the equipment of tomorrow.”